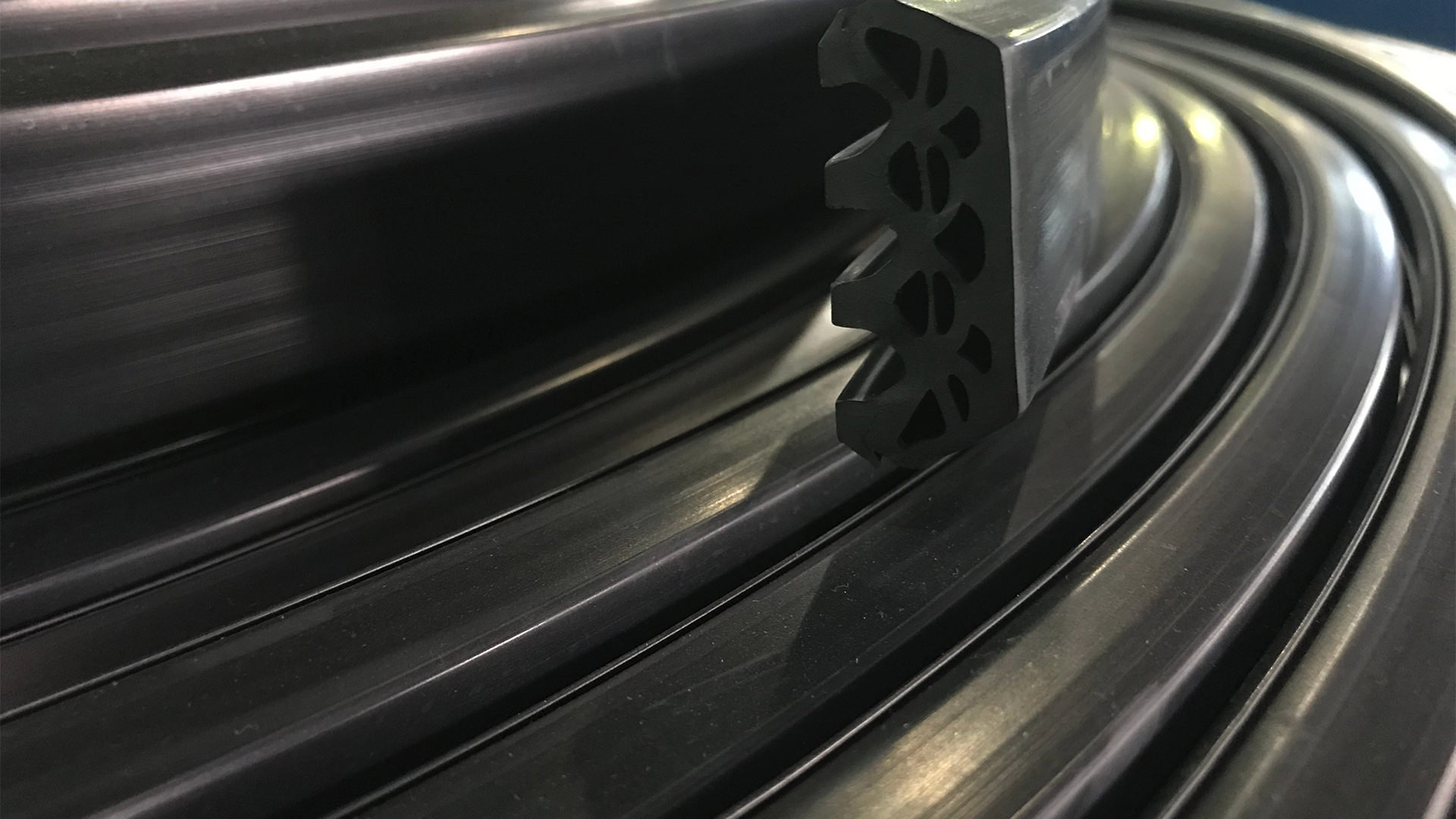

Rubber Lining

Bahrain Rubber specializes in providing superior corrosion resistance rubber lining services, an essential protective coating applied to a range of substrates including metals and concrete. This service is crucial for industries like chemical processing, oil and gas, mining, water treatment, and power generation, where materials are frequently exposed to harsh chemical environments. The rubber linings, made from high-quality synthetic rubber compounds, are meticulously applied using specialized techniques to ensure a seamless and enduring bond. This protective barrier is highly resistant to acids, chemicals, and other corrosive substances, significantly extending the lifespan of the treated equipment.

Our rubber lining solutions are tailored to meet the specific needs of our clients and are available in a variety of types, such as natural rubber, butyl, EPDM, neoprene, and Hypalon, each chosen for their unique resistance properties to suit different applications. Bahrain Rubber is equipped to handle both on-site and in-house projects across the Gulf region and the Middle East, demonstrated by our successful completion of significant projects including the lining of tanks, pipes, and valves in key sectors. With state-of-the-art facilities, including on-site boilers and autoclaves for curing, and a team of skilled professionals, Bahrain Rubber is committed to delivering durable and reliable rubber lining services that protect your investments and enhance operational safety and efficiency.