CONVEYOR BELT SUPPLIES

BRC ROBUST-General Purpose Belts

We manufacture and supply EP & NN General Purpose Conveyor Belts as per DIN X, DIN Y, M-24, M-20, N-17, etc. standards.

General Purpose Conveyor Belts are used to convey moderately abrasive material like aggregate, sand, iron ore, slaked lime, etc.

BRC INTENSE-Heat Resistant Belts

Conventional rubber covers have limited heat resistance. For special applications like carrying high-temperature materials like Cement, Clinker, Limestone, Hot Chemicals, Phosphates, and Fertilizers, BRC offers conveyor belts capable of withstanding elevated temperatures of +200° C and resist cracking and hardening for a much longer period in operation.

BRC BLAZE-Fire Resistant Belts

BRC offers fire retardant and resistant belts to mitigate any fire hazard risks that may incur due to on-site circumstances.

BRC BLAZE Belts meet International standards like FR-AS, MSHA (2G, Part 14), CAN-C, DIN-K, DIN-S, SANS 971:2013, etc.

BRC SLICK-Oil Resistant Belts

BRC SLICK Belts are suitable for conveying a wide range of materials that may either contain or are coated with oil. Special rubber compounds are used to ensure that there is no "swelling" on the belts while carrying oily materials like fertilizer products, pet coke, soya and grain, metal turnings, scrap recycling, hot Asphalt, and ready mix.

BRC ASCEND-Chevron Belt

Conveyor belts, conveying material at ascending angles face a peculiar problem of the material rolling back. To counter the roll back of material, the conveyor belt speed is increased. But this results in higher power consumption and costs.

BRC ASCEND Conveyor Belts have several profiles and cleats which ensure that there is no roll back of material.

BRC BOLT-Tear Resistant Belts

Especially in heavy duty mining, conveyor belts carrying large sized lumps have a significantly lower life due to continuous abuse resulting in premature failure caused by rip, tear and carcass fracture.

BRC BOLT is the belt for such challenging applications. BRC BOLT belts are manufactured using a specially designed fabric having high tenacity, straight warp threads and dense weft yarn construction. These belts are offered in single or two ply constructions.

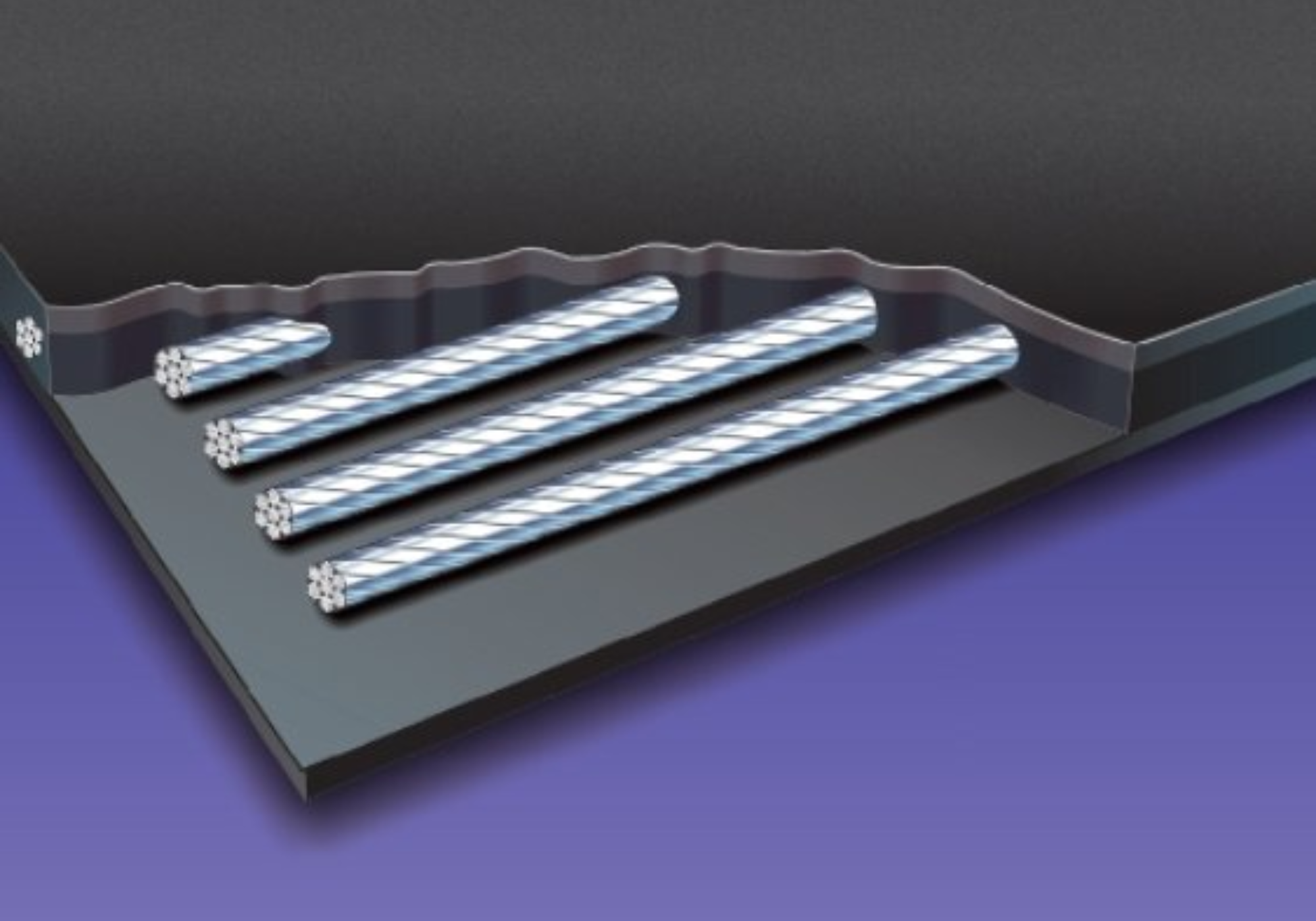

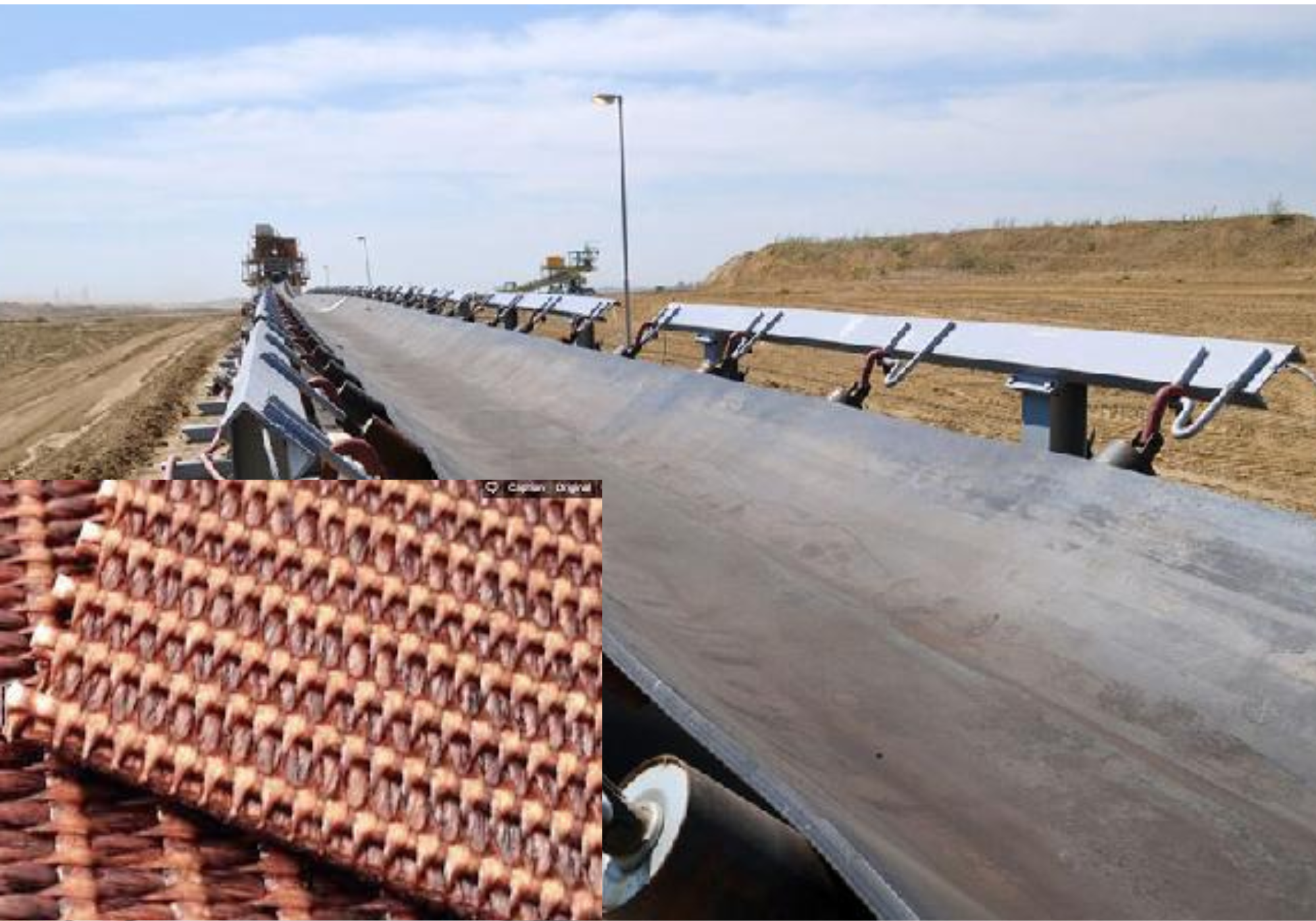

BRC GRIT-Steel Cord Belts

Steel cord conveyor belts are highly wear-resistant and used principally for long-haul conveying, heavy loads and physically demanding applications. They are especially suitable for high-mass or high-volume flows and for abrasive materials.

BRC GRIT Steel Cord Conveyor Belts offer higher strength, higher abrasion resistance, higher impact resistance, and a long life.

BRC ASCEND-Steep Incline Belts

Space is a major constraint in setting up cost effective conveyor system in any industry. Hence, the conveyor systems are designed with high inclination so as to accommodate it in the given constrained space.

BRC ASCENT STEEP INCLINE belts are installed in areas where the conveyor inclination angle is steep. These belts are modern age Bucket Elevator Box Belts. These Belts are made with Cleats and Sidewall. The concept of these belts is to carry materials on steepest angle up to 90 degree with zero spillage.

BRC IMPACT-Impact Resistant Belts

Large lumps of material are dumped on conveyor belts with great force. This constant impact causes a great reduction in the life of the belt. The carcass of the belt, which is basically the spine of the belt, fractures, and this leads to belt failure.

To obtain higher carcass strength, BRC IMPACT Conveyor Belts use a specialized fabric that retains significant strength after repeated impact loading and thereby enhances the life of the belt. It offers a higher impact and tear resistance of up to 2.5 times higher than conventional EP / NN belt constructions.

CONVEYOR BELT ACCESSORIES

IDLERS

IMPACT ROLLERS

RETURN ROLLERS

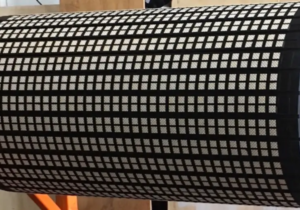

CERAMIC PULLEY LAGGING

RUBBER PULLEY LAGGING

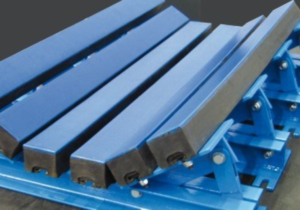

IMPACT BARS

FLEXECO PRODUCT RANGE

Belt Cleaners

Mechanical Fasteners

Impact Beds

Belt Trainers

FLEXCO BELT MAINTENANCE TOOL

CONVEYOR BELT SPLICING & REPAIRS

BRC has an experienced Conveyor Belt Splicing team and has also invested in the latest technologies of vulcanizing presses and equipment to continually improve conveyor belt splicing techniques.

BRC offers Hot Splicing, Cold Splicing, as well as Mechanical Splicing solutions, both ON SITE as well as within our Facility.

BRC technicians are equipped with all necessary tool kits and are well-trained. In addition to splicing, BRC also executes belt installation projects.

BRC believes in "ON CALL MOBILIZATION". It has a mobile belt repair and splicing unit which jumps into action at the first call.

The BRC team carries out the work in accordance with international standards and procedures.

BRC also supplies endless belts & vulcanizing materials as well as kits.