BRC Rubber Product

Bahrain Rubber produces a wide range of rubber products serving a number of industries and covering a wide range of application. Being the first in the market has benefited us in pioneering in various application, and creating uniques solutions has become our trade mark.

Our products range from custom designed solutions such as Seals, Gaskets, Moulding, Extrusion, lining and Conveyor Belt Services to commercial items, like building protection systems.

The Sectors we serve are wide and not limited to Bahrain only, furthermore we serve ministries, costal guards and Marien related services.

Rubber product range

Bahrain Rubber offers a variety of rubber products in the following fields:

Seals

A wide range of Door and Window Sealing Systems, Curtain Walling Gaskets (both for Stick System and Unitized Systems), Seals for Patio and Swing Entrance Door Systems, Facade Systems, Skylight and Sliding Door and Door and Windows systems.

Gaskets

Gaskets are mechanical seals that prevent leaks between separate substrate sections. They are occasionally made of hard material because they must be durable enough to withstand extreme pressures and wear. These gaskets, can be made out of synthetic rubbers. These thick rubbers are robust enough to handle the kinds of extreme pressure and wear associated with gasket applications.

Diaphragms

BRC provides a variety of custom molded rubber diaphragms designed and engineered for specific industry applications, including pneumatic actuators, pumps and control valves. BRC has years of experience in the gasket manufacturing industry has proven that certain applications demand that a rubber elastomer layer must be very flexible and tough in order to withstand repeated flexing over a long lifetime.

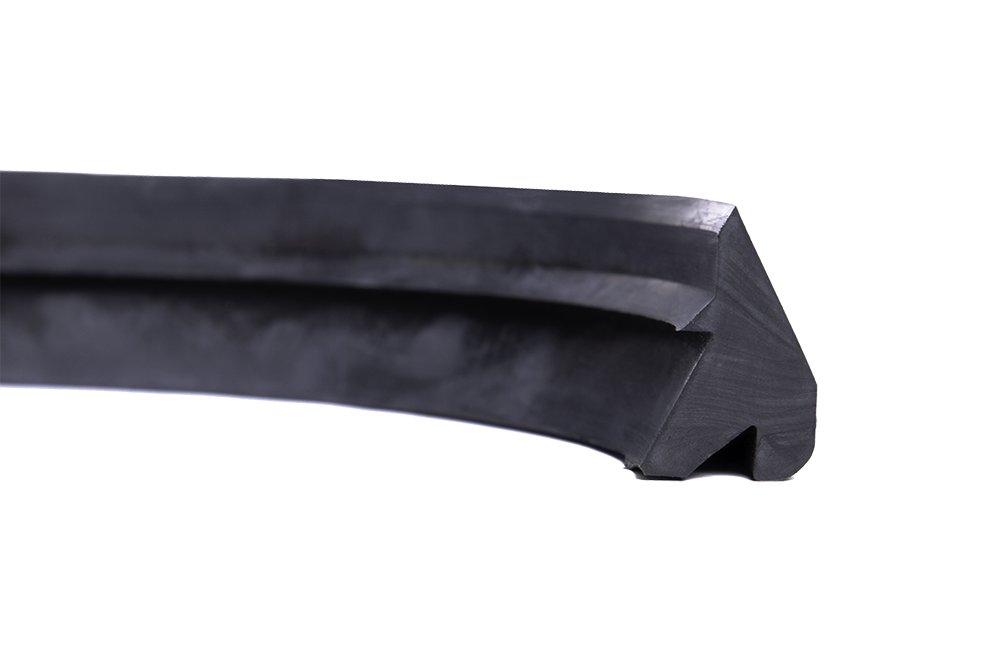

Extrusion

Extrusion is a process used to create objects of a fixed crosssectional profile. A material is pushed or drawn through a die of the desired cross-section. The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections and work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms finished parts with an excellent surface finish.

Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). be done with the material hot or cold.

Extrusion remains a popular choice for many manufacturers because of the neat, uniform way extruded rubber products can be produced. A great variety of shapes can be created for any industrial need, including hollow designs that greatly reduce material cost and create flexible, lightweight product.

Conventional Extrusion

Extrusion is a process used to create objects of a fixed crosssectional profile. A material is pushed or drawn through a die of the desired cross-section. The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections and work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms finished parts with an excellent surface finish.

Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). be done with the material hot or cold.

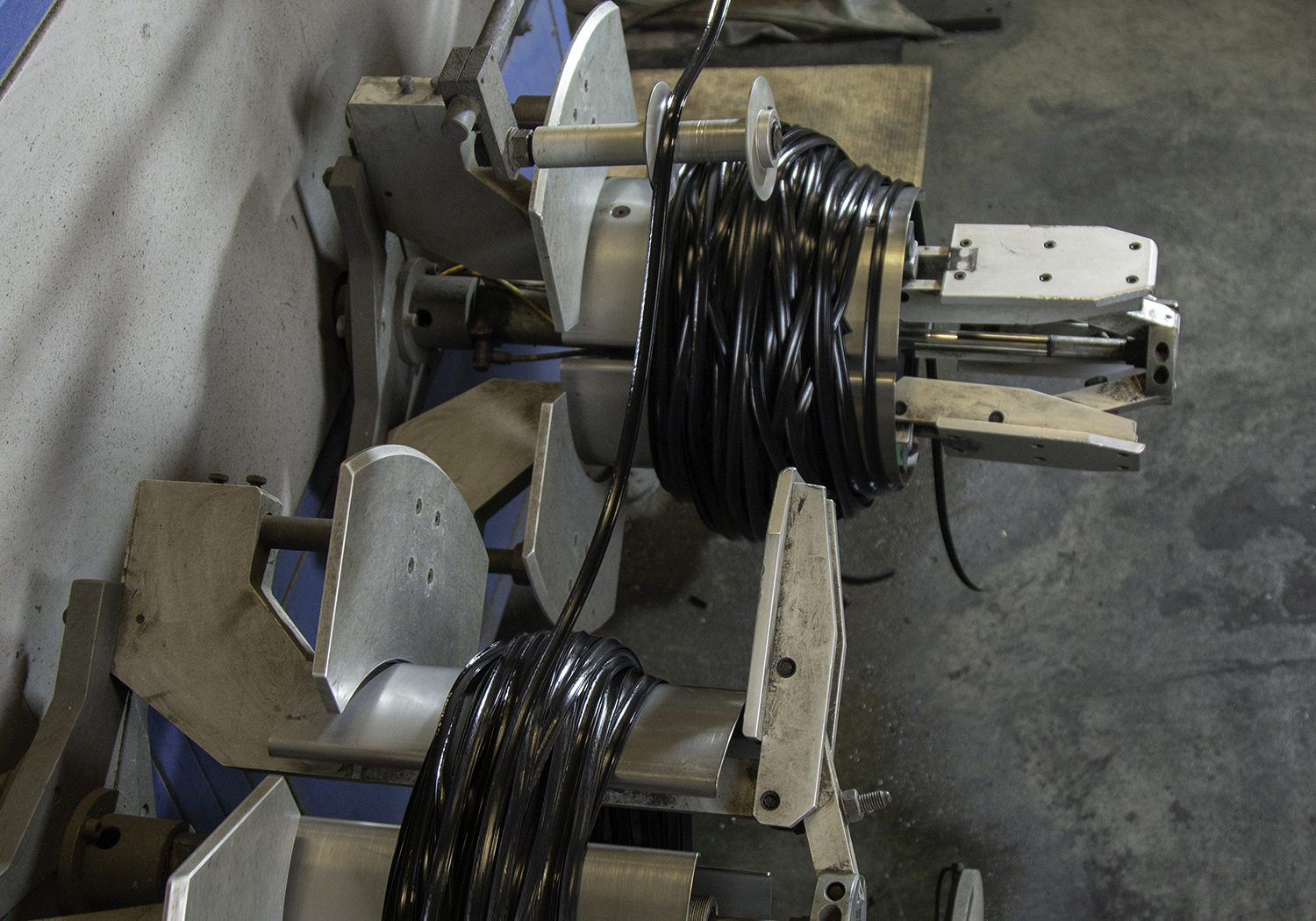

Continuous Vulcanization

Continuous vulcanization has the advantage of combining processing and curing steps into one continuous operation on many extruded profiles. Traditionally, extruded profiles and hoses have been separately processed and vulcanized. During the processing step, the profile is extruded in a continuous operation, but the extrudate is accumulated for later batch vulcanization, in a steam autoclave.

Aluminium Profiles

BRC serves a wide section of aluminum manufacturers with special section for construction of buildings in Bahrain, KSA and Kuwait. EPDM is used in the manufacturing of architectural profiles. EPDM is a highly valued material in the Building Construction Industry (primarily aluminum Fabrication Segments and expansion joint segment), which represents which represents 40- 45 % of world wide EPDM usage.

Lining & Conveyor

Lining

Rubber lining is applicated as a Solution for tanks pipes and vessels in various industries such petrochemical industry and related logistics. Corrosion resistant lining is carried out for different vessels, tanks, pipes, flanges and valves off various application. BRC carries out rubber lining . We process unvulcanized linings for shop and field use, pre-vulcanized for large erected tanks, and self-vulcanizing or chemical curing rubber for repair works of rubber lining.

Rubber Rollers

BRC services rubber rollers, rubber covering, diamond rolls etc.

Conveyor Belt

BRC is introducing conveyor belt production line, including lagging splicing impact belts, rollers for the conveyor belts and other neccessary services related to conveyor belts.

BRC's Subsidiary Rubber World is for commercial items and finished products.

See our Products.